PRODUCT CENTER

Contact Us

E-mail:

Mobile Phone:

Address:

Room 6010, Floor 6, Zhonghai City Plaza, Huangbohai New District, Yantai City, Shandong Province,China

304 304L Stainless Steel Pipe

Product Details

Description

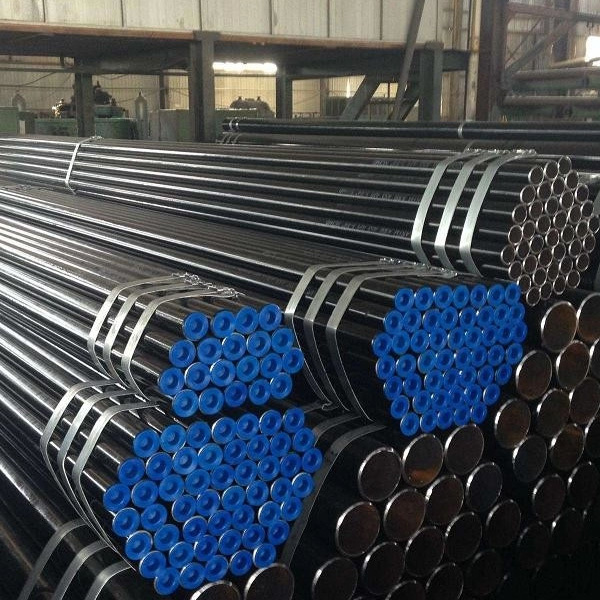

304 304L Stainless Steel Pipe is a pipe material with high corrosion resistance and high strength. It is made by heating a stainless steel blank to a high temperature and then using a piercing machine. This manufacturing method maintains the uniformity and consistency of the pipe, thus ensuring the quality and performance of the pipe.

Stainless steel seamless pipes have many advantages. First of all, it has excellent corrosion resistance and can be used for a long time in acidic and alkaline environments without corrosion. Second, it has good strength and toughness, and can withstand the stress of high pressure and high temperature environments. In addition, the inner wall of the stainless steel seamless pipe is very smooth and will not block the fluid, so it is suitable for the occasion of conveying high-viscosity fluid and solid particles.

Stainless steel seamless pipes are widely used. In petroleum, chemical industry, medicine, food and other fields, stainless steel seamless pipes are widely used to transport liquid and gas. In the petroleum industry, it is used to transport crude oil, natural gas and petroleum products. In the chemical industry, it can transport various chemicals. In the pharmaceutical industry, stainless steel seamless pipes are used for the delivery of drugs and pharmaceutical equipment. In the food industry, it can convey food and beverages.

The manufacturing process of stainless steel seamless pipe is very complicated and requires multiple processes. First, choose the appropriate stainless steel material, and heat and perforate it. Then, the perforated tube blank is drawn into a seamless tube by a drawing machine. Next, the surface treatment and performance adjustment of the seamless pipe are carried out by methods such as pickling and heat treatment. Finally, the quality inspection of the seamless pipe is carried out to ensure that it meets the relevant standards and requirements.

In a word, stainless steel seamless pipe has the characteristics of corrosion resistance, high strength and smoothness, and is widely used in petroleum, chemical, pharmaceutical and food industries. Its manufacturing process is complex and requires a high degree of technology and quality control. With the development of industry and technology, the application of stainless steel seamless pipes in various fields will become more and more extensive.

key word : Seamless Steel Pipe

APPLICATION FIELD

That apply to engineering, coal mine, textile, electric power, boiler, machinery, We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. We′re pleased to get your Inquiry and we will come back to as soon as possible.

Mechanical

Pressure vessel

Power plant

Chemical plant

Oil Pipelines

Natural gas transportation

Water pipes

Automobile making

Bridge

Architecture

RELATED PRODUCTS

Get a Free Quote